Competencies for Process Engineers

The process owner's responsibility is to perform two critical functions in support of operations:

- Continuous Process Improvement

And

- Root Cause Problem Solving

In order to successfully accomplish these fundamental tasks, the engineer will need to master several skills (usually not taught in College).

Before discussing the details of what skills the process engineer requires, I would like to share my opinions on how training efforts may fall short of target.

During my 30 years in manufacturing engineering I have found that an overwhelming majority of internally managed training programs fail to accomplish their objective for the following reasons:

- The participants do not understand how and why such skill would help them in their job. Lack of pre-training project assignment.

- Concepts are usually taught in isolation, often starting from the very basic and progressively moving to more complex topics without much integration.

- Delivery of content often leaves participants confused, unmotivated, and bored.

- Absence of management plan for encouraging application of the learned techniques immediately upon return to work.

I found that the most effective course designs are those which incorporate a balanced mix of delivery methods.

I propose that lecturing should be minimized as much as possible to facilitate and promote experiential learning in team settings. Exercises would be based on real and pertinent problems. A top-down understanding of why and when specific tools are applied would be covered before learning how to use them. This would be accomplished by utilizing custom tailored examples which showcase the application and integration of the required competencies, at the very beginning of the course.

Certification for competencies would be required based on the successful passing of a final test in conjunction with successful application of competency upon return to work.

I believe that this approach is absolutely necessary for teaching Statistical concepts. Probability theory and inference statistics such as hypothesis testing are often taught at the beginning of most introductory programs leaving participants disillusioned and uncomfortable about the subject matter. It is my opinion that a more successful approach would be to design and deliver an introductory course with the specific objective to develop a lifelong interest and predisposition for continuous learning in this subject matter. The introductory course would teach the validity and practicality of fundamental statistical concepts such as:

- Variation exists in all processes, including measurement systems

- The key to success is to reduce variation

- A process is in control only in the absence of special causes

- Every experiment must be designed to ensure:

1. control of outside variables,

2. proper randomization,

3. replication (for estimating variation from measurement)

- All processes in life are affected by interactions

- One factor at a time experimentation prevent us from discovering interactions which are often at play.

I propose the development of such Introductory Course as a prerequisite to Green Belt and Process control training. Perhaps this may be incorporated into a Yellow Belt Training Program.

The objective of this document is to propose such competency- based program.

Competencies for Problem Solving and Process Improvement Efforts

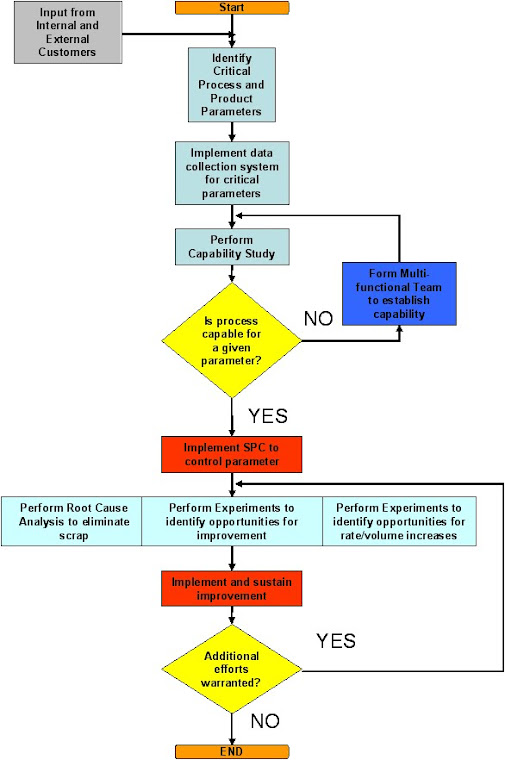

Finally, the following table provides a comprehensive list of recommended competencies required for a process engineer to successfully perform the two functions of process improvement and problem solving. Statistical competencies (shown in blue) would be provided only after successful completion of the introductory course discussed above.

| Road Map | Competencies |

| Define The Problem | Effective Team Participation and Building, Running Successful meetings, Pareto Charts, Flow Charting (Visio), Operational Definition, Run Charts, SPC Charts, Measures of Central Tendency, Measures of Variation, Introductory Capability Analysis, Definitions of machine utilization rates, Introductory Project Management |

| Develop Strategy | Cause and Effect Diagram, Brainstorming, Gage R&R, Iso plot, Pareto Principle |

| Generate Clues | Data Mining techniques, Affinity Diagrams, Cum Sum, Introductory DOE and fundamentals of effective Experimentation, Linear Regression |

| Find and confirm root cause | Introductory Anova, Effective Presentation skills |

| Implement solution | Identifying and Overcoming Road Blocks, Technical Document writing, Effective PFMEA |

| Control | Effective Process Control, Effective Training, SPC Charts, Run Charts |